Working principle:

ZJ series fluidized bed ultrafine pulverizer uses several relatively arranged nozzles to form high-speed airflow, and then uses high-speed airflow to accelerate the material to supersonic speed so that it collides with each other at the intersection of nozzles to achieve the purpose of ultrafine pulverization. The crushed material enters the classifying chamber of the classifier with the updraft. Because of the high-speed rotation of the classifying rotor, the particles are subjected to centrifugal force produced by the classifying rotor and centripetal force produced by the viscous action of the airflow. When the centrifugal force of the particles is greater than the centripetal force, that is, the coarse particles with the size of the classifying particle return to the grinding chamber and continue to impact and crush, the fine particles enter the cyclone separator and collect Collection, the gas is discharged by the induced draft fan.

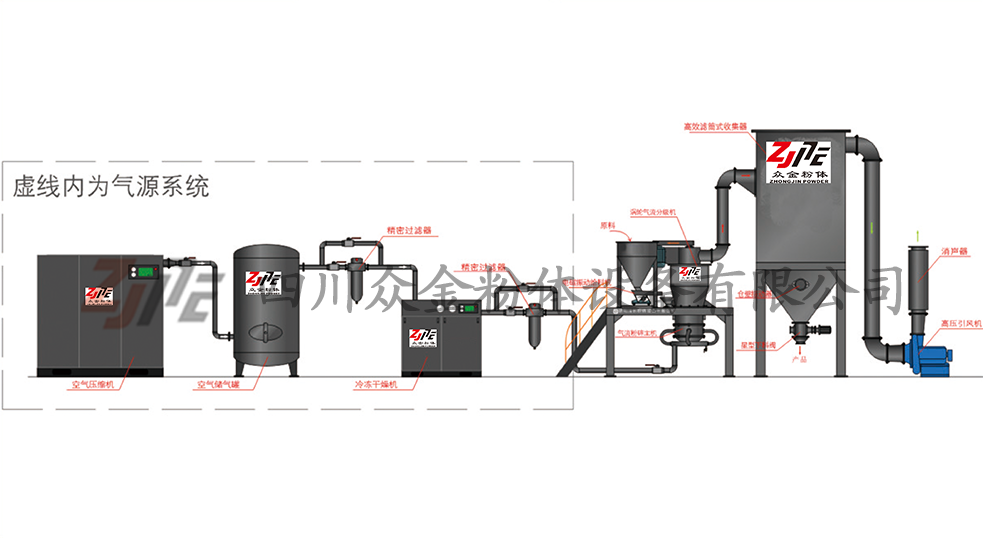

ZJ series fluidized bed airflow crusher is a renewal product of traditional fluidized bed airflow crusher, jet airflow crusher, horizontal airflow crusher and other types of airflow crusher. The equipment is mainly composed of crushing main machine, high-precision eddy classifier, cyclone collector, bag dust collector, air compressor and so on. Full utilization of jet energy is the greatest feature of this machine.

Working principle:

ZJ series fluidized bed ultrafine pulverizer uses several relatively arranged nozzles to form high-speed airflow, and then uses high-speed airflow to accelerate the material to supersonic speed so that it collides with each other at the intersection of nozzles to achieve the purpose of ultrafine pulverization. The crushed material enters the classifying chamber of the classifier with the updraft. Because of the high-speed rotation of the classifying rotor, the particles are subjected to centrifugal force produced by the classifying rotor and centripetal force produced by the viscous action of the airflow. When the centrifugal force of the particles is greater than the centripetal force, that is, the coarse particles with the size of the classifying particle return to the grinding chamber and continue to impact and crush, the fine particles enter the cyclone separator and collect Collection, the gas is discharged by the induced draft fan.

ZJ series fluidized bed airflow crusher is a renewal product of traditional fluidized bed airflow crusher, jet airflow crusher, horizontal airflow crusher and other types of airflow crusher. The equipment is mainly composed of crushing main machine, high-precision eddy classifier, cyclone collector, bag dust collector, air compressor and so on. Full utilization of jet energy is the greatest feature of this machine.

Technological process:

Scope of application:

With its unique working principle, this series of grinding classifier can process superfine powder of various materials, such as dry, high purity and low temperature. It is widely used in chemical industry, mining industry, abrasives, battery materials, refractory materials, non-metallic minerals, metallurgy, building materials, pharmaceuticals, food, pesticides, feed, new materials, environmental protection and other industries, as well as in superfine grinding, dispersing and granulation of various dry powder materials. Shape.

Typical materials:

Silicon carbide, garnet, ceramic corundum, boron carbide, diamond, tungsten carbide, phosphorus iron; calcium carbonate, quartz, diatomite, calcium hydrogen, bentonite, talcum, mica, wollastonite, high purity pigments, luminescent powder, cell phone battery powder; pollen, auxin, food additives, antibiotics, contrast drugs, Ganoderma lucidum, Pearl powder; pesticides, polytetrafluoroethylene, etc.

Main technical parameters

Model

| Air flow | air pressure | Max feed Size | Product Size | Capacity | Power |

ZJ-QLM50 | 1 m3/min | 0.7-1 Mpa | <1 mm | 0.2-200um | 0.2-5kg/h | 9.5kw |

ZJ-QLM100 | 3 m3/min | 0.7-1 Mpa | <3 mm | 0.2-200um | 5-20kg/h | 26kw |

ZJ-QLM200 | 6 m3/min | 0.7-1 Mpa | <3 mm | 0.2-200um | 20-90kg/h | 47kw |

ZJ-QLM300 | 10 m3/min | 0.7-1 Mpa | <3 mm | 0.2-200um | 30-150kg/h | 79kw |

ZJ-QLM400 | 20 m3/min | 0.7-1 Mpa | <3 mm | 0.2-200um | 60-600kg/h | 137kw |

ZJ-QLM600 | 40 m3/min | 0.7-1 Mpa | <3 mm | 0.2-200um | 100-900kg/h | 290kw |

Application site: