Precision air classifier

精密气流粉碎分级机The working principle of:

The classifier, dust remover and induced draft fan constitute a grading system. Material under the action of a draught fan by the classifier high speed movement to bottom into the mouth with the increased flow classification, rotating at high speed grading strong eddy current under the action of centrifugal force, make the thickness of material separation, conform to the requirements of the particle size of the fine particles, through the classification of blade clearance into cyclone separator or dust collection, coarse particle entrainment of fine particles bump wall disappeared rate after, along the wall fell to second FengKouChu, by the strong elutriation effect of secondary air, make granules in separation, fine particles up to second grade classification area, coarse particle fell to discharge mouth eduction.

Equipment performance characteristics:

1, no water, washing, completely dry production, can get a narrower particle size distribution, non-polluting abrasive powder; A grade can be processed into any brand of products according to the current standards at home and abroad (such as: national standard W63 ~ W3.5, Japanese standard 240# ~ 3000# and European standard f230/53 ~ f1200/3). Single number yield reached more than 75%.

2. High grading accuracy, more accurate cutting particle size, lower required speed and long service life.

3, independent casting bearing, never deformation, long service life.

4, optimized transmission design, bearing force is small, long service life.

5, unique pipeline design, help powder flow, help reduce wear, easy to wear parts easy to replace and deal with.

6. The company's unique variable frequency feeding system is conducive to the dispersion of materials, the continuous, uniform and stable feeding, and the control of product particle size.

7. Unique design of internal circulation secondary air, adjustable clearance of grading cone, greatly reduced gas consumption, reduced energy consumption of grading, and thorough extraction of fine powder.

8, the separation of the flow path, help to reduce the bottom of the grading wheel wear, and more conducive to the control of large particles.

9, completely closed negative pressure operation, no dust pollution.

10, good stability, a fixed parameter adjustment, stable production;

11. In particular, the core competitive advantage of more thorough extraction and better stability of fine powder has been widely recognized in the industry.

12. The whole system adopts automatic control, which can realize one-key start and stop, simple and convenient operation and connection with central control can realize remote control.

◆The general application:

What ZJ had - F series precision air classification function classification that can't be graded on ordinary separation equipment materials, especially suitable for processing strict rules limit maximum particle and narrow particle size distribution of products, such as coarse whiting, kaolin, talc, barite powder, copier toner, coating, mica, graphite, auxin, aluminum hydroxide, etc.

◆ High purity applications:

The zj-f series precision air classifier

can be used for materials that have strict requirements on the content of impurities or materials that are extremely sensitive to iron, and can meet the requirements of particle size and particle size distribution at the same time. Typical materials are: phosphor, titanium dioxide, starch, silica gel, aluminum, copper, luminescent powder and a variety of high purity pigments.

◆ Abrasive and hard materials:

Zj-f series precise air classifier

can grade hard materials with mohs hardness above grade 7. The application of vertical eddy current classifier makes the equipment wear very little. The speed of the classifying wheel can be adjusted and the grinding parameters can be optimized. Typical products are: diamond, silicon carbide, boron carbide, tungsten carbide, special ceramics, emery and so on.

◆ Food, health care products, medicine:

Zj-f series precision airflow grading function ultra-fine processing medicine, food and health care products, its low-temperature grinding, high-purity operation and high processing finish and easy cleaning machine features, making zj-f series ideal for pharmaceutical, health care products and food industry, not only improve the bioavailability and efficacy of drugs, but also reduce the production cost. Typical products are: pollen, hawthorn, mushroom, pearl powder, stomach medicine, nimodipine, antibiotics, imaging drugs, ganoderma lucidum, gallnut, polygonum multiflorum, etc.

◆ Other industries:

Zj-f series precise air classifier

can be used in closed cycle system with inert gas to grade the articles which are easy to burn, oxidize and explode. Such as carbonyl iron powder, nickel powder, tungsten cobalt alloy powder, refined selenium powder

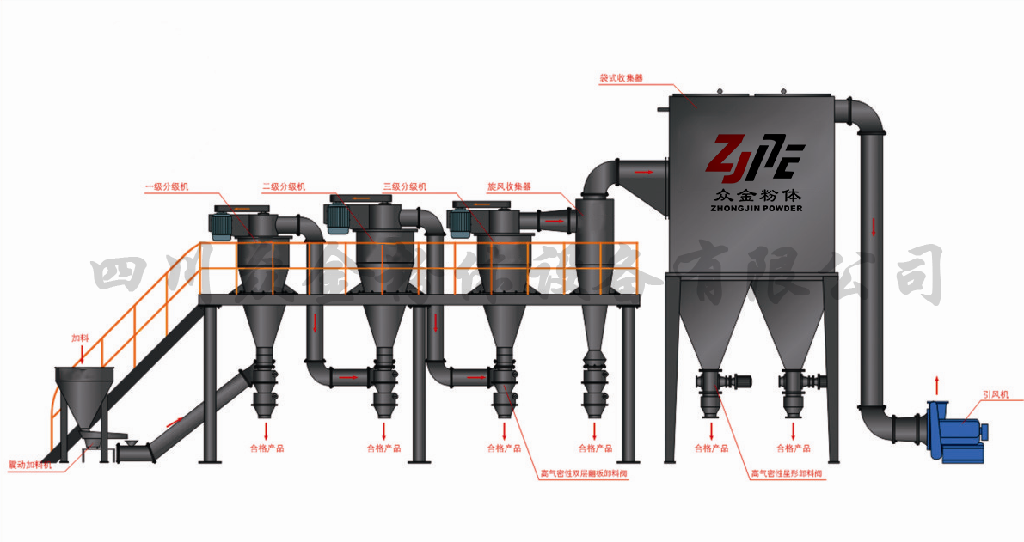

The process flow

technical parameters

Model

| Grading size range

| Capacity

| Power

|

ZJ-F100 | 0.2-200 um | 5-30 kg/h | <10 kw |

ZJ-F200 | 0.2-200 um | 50-200 kg/h | <15 kw |

ZJ-F300 | 0.2-200 um | 50-600 kg/h | <20 kw |

ZJ-F400 | 0.2-200 um | 300-1300 kg/h | <30 kw |

ZJ-F600 | 0.2-200 um | 600-2000 kg/h | <50 kw |

Note: the above box only lists some types of equipment. Our company can scientifically combine the grading equipment according to the actual needs of users for multi-level grading, that is, one set of equipment can produce multi-level products at a time. For example, ZJF series precision air classifier can produce 1-5 standard finished products at a time. Welcome to buy!

The case shows: