Ultrafine powder optimization project

Scope of application:

Collection of ultrafine and ultrafine powders and dust treatment during production;

All kinds of difficult waste gas treatment, involving power plants, steel mills, smelters, oil refineries, plastic factories, chemical plants, pharmaceutical plants, animal husbandry plants, restaurants and restaurants lampblack purification treatment;

Our company can design different structures and filter materials (such as high-temperature, flammable and explosive powder, high-electrostatic powder, high-humidity and high-adhesion powder, corrosive powder, etc.) according to the characteristics of dust treatment and the operating environment.

Dust collection efficiency can be up to 99.99%, the dust concentration of filtered gas <10mg/m3.

Central dust removal products:

Introduction to energy-saving and environment-friendly central dust removal system:

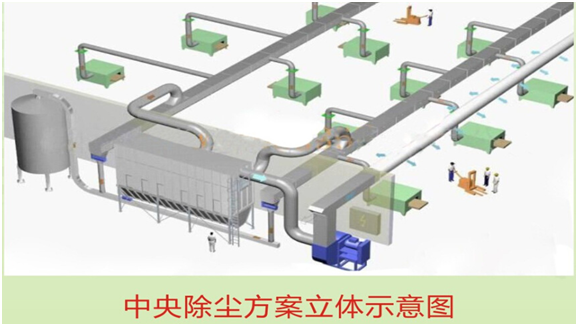

The central dust removal system consists of: vacuum cleaner, dust collection hose, stop valve, dust collection pipe, electrical control system, dust remover (according to dust characteristics), soil construction, fan, etc. It is mainly developed for the centralized collection and treatment of the dust and particulate matter generated in the production and processing process of the machine equipment in the industrial production and processing workshop

Features of energy-saving and environment-friendly central dust removal system:

1. The frequency conversion control system is adopted to automatically adjust the running condition of the fan according to the number of each suction port, so as to reduce the power consumption and achieve the energy saving effect (when running at full load, about 20% of the power can be saved, and about 30% of the power can be saved when running at 70% of the load).

2. High dust removal efficiency, safety, reliability, standard discharge.

3, adopt galvanized spiral dust removal pipe, pneumatic conveying pipe, with good sealing performance, good strength and rigidity, small ventilation resistance and other characteristics.

Cyclone dry - wet combined fire and explosion - proof central dust removal system:

According to the new environmental protection law, industrial waste gas and dust are the most important air pollutants in furniture factories. As we have learned, what furniture factory USES commonly is small-sized cloth bag dust remover, at cleaning workshop dust, but the effect that blows dust in working process to woodworking machinery is not apparent. Pulse bag dust removal system can meet the dust removal needs of most workshops, but it is not effective for the volatile gas in the paint workshop, and it has a large investment and high cost. Currently, only a few large furniture factories adopt it. A kind of initial investment and use cost is lower, dust and waste gas can purify the new dust removal equipment, applied in the redwood furniture factory, wood door factory, furniture factory, bamboo and wood products industry, perhaps in the right...

Dust and exhaust gas co-purification -- cyclone combined dry and wet central dust removal equipment

This what ZJ had - XFGSZH series new fire, explosion-proof type central dust removal equipment is also known as "cyclone wet combined fire, explosion-proof carpenter central dust collection system", is an amalgam of cyclone dust removal and wet dust removal, taking water as the final cleaning medium, not only suitable for bamboo and wood products industry carpentry workshop dust treatment, also applies to the paint, polishing workshop purification of volatile organic compounds.

For most redwood furniture, bamboo products enterprises, the primary factor in the investment of a certain type of dust removal equipment is price. Cyclone dry-wet combined fire-fighting and explosion-proof dust removal equipment is small in size and the cost is between the pulsed bag dust removal system and the small bag dust remover.

First of all, in the principle of cyclone dust removal, the operation of the fan equipment by the small resistance, determines the cyclone dry and wet combined fire, explosion-proof dust collector more energy saving. As we have learned, the resistance of impulse bag type dust collector is in commonly 1500 pa -- 2000 pa, the resistance of cyclone dry wet combination type fire control, explosion-proof dust collector has 800 pa only -- 1500 pa. This means that the efficiency of the latter is 1-2 times that of the former under the same wind volume.

High frequency of filter bag replacement, high demand, high frequency of pulse valve and blanking machine maintenance, so that the use of pulse bag dust removal equipment also needs a lot of investment. Cyclone dry and wet combined fire, explosion-proof dust removal system is "leather" more, it is the medium of water, recyclable, maintenance rate is very small.

In addition, the cyclone dry-wet combined fire control and explosion-proof dust removal system can also effectively reduce fire hazards, thus avoiding the huge fire losses caused by dust removal equipment.

In annatto, plate, solid wood furniture, wooden door, floor enterprise other than the bamboo and wood products processing enterprises, small and medium-sized enterprises to adopt cyclone wet combined fire, explosion-proof type common woodworking central dust collection system, suitable for: flammable and explosive enterprise whole factory central dust, inflammable and explosive dust purification treatment, wood dust, carpentry workshop dust, dust woodworking machine, woodworking equipment, dust removal, remove dust furniture factory, wooden door factory dust, the floor factory dust removal, bamboo and wood products factory dust, dust removal, Chinese herbal medicine plant biomass boiler dust removal, foundry dust removal, boiler dust, inflammable and explosive dust purification processing industry.