Titanium dioxide special crushing classifier

Performance characteristics:

Titanium dioxide (TiO2) is an important inorganic chemical product, which has important applications in coating, printing ink, papermaking, plastics and rubber, chemical fiber, ceramics and other industries. Titanium dioxide is a major source of titanium dioxide, a white pigment. The scientific name is titanium dioxide, and the molecular formula is TiO2, a polycrystalline compound, with regular particle arrangement and a lattice structure. Titanium dioxide has the lowest relative density. The production process of titanium dioxide includes sulfuric acid and chlorination. [1]

Application:

The main application fields of titanium dioxide: coating, plastic, ink, papermaking, of which coating accounts for 60%, plastic accounts for 20%, papermaking accounts for 14%, other (including cosmetics, chemical fiber, electronics, ceramics, enamel, welding rod, alloy, glass and other fields) accounts for 6%.

Equipment selection: according to the characteristics of titanium dioxide can choose ZJ series double jet flat airflow crusher

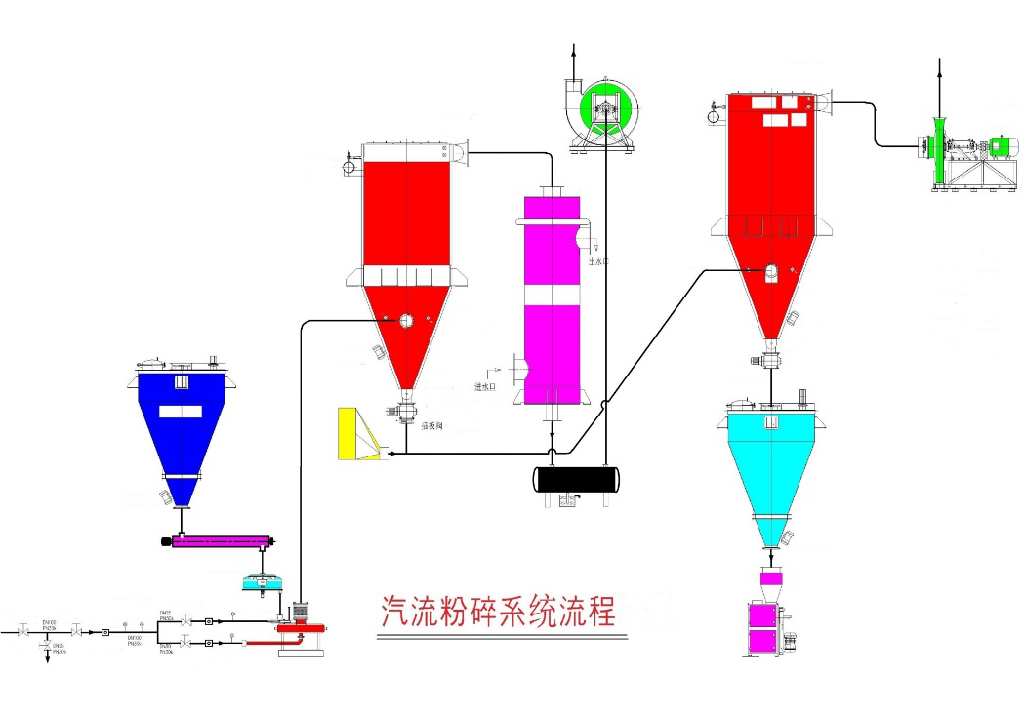

Process flow:

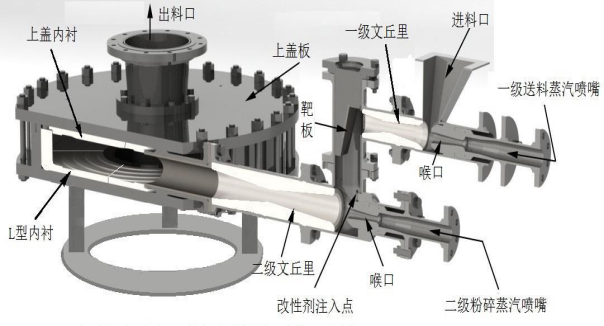

Equipment overview:

ZJ ultra-fine and ultra-micro pulverizer steam double jet flat airflow pulverizer is our company according to the crushing requirements of titanium dioxide, namely narrow particle size distribution, less inclusion, good dispersion; And titanium dioxide material viscosity, poor fluidity, fine particle size and easy to adhere to the wall and other characteristics, the development of titanium dioxide final grinding special steam flow mill.

At present, domestic and foreign titanium dioxide manufacturers choose flat type (also known as horizontal disc type) airflow mill with self-grading function as the final crushing equipment of titanium dioxide. And the use of superheated steam as the crushing medium, crushing at high temperature, can improve the dispersion of titanium dioxide application, increase the mobility of titanium dioxide. Low energy consumption, only 1/3 ~ 2/3 of the compressed air.

ZJ steam double jet flat airflow pulverizer can be used to improve the dispersion of titanium dioxide in different application systems. As the most important equipment for airflow crushing, the quality of airflow crusher directly determines the quality of products. Therefore, the airflow crusher is required to be designed reasonably, well-made, with large impact kinetic energy, good grading effect, abrasion resistance and high temperature resistance.

Equipment features:

Compared with the traditional flat-type airflow crusher, it has been greatly improved and improved. The machine makes full use of all the energy of the superheated steam, and the materials are in the same equipment after two times of crushing and grading, so that the product particle size is finer, the particle size distribution is narrower and the quality is better.

1. The special inlaying structure of superhard wear-resisting material used in the lining greatly improves the service life and crushing effect of the airflow crusher.

2. High fineness: d90=0.3~10 m, narrow particle size distribution and no large particles.

3. High grinding efficiency, low energy consumption, 30% energy saving compared with other types of airflow grinding;

4, using Al2O3, SiC or

Pu (plutonium) is easy to wear, low wear, less product pollution, can be processed without iron pollution powder products and mohs grade materials, especially suitable for the production of titanium dioxide chloride method;

5. Compact structure, low noise and relatively low cost.

6. ZJ steam double flat steam flow crusher adopts pipe automatic classification, which is easy to realize when superheated steam is used as working medium for crushing.

7. The inner lining of the crushing cavity is made of super wear-resisting and impact wear-resisting material, and the special inlay can cushion the structure, which effectively overcomes the problem that wear-resisting material is easy to break up and ensures its service life.

Equipment parameters:

设备型号

Model | 介质温度 Medium temperature | 料气比 Gas solid ratio | 成品细度 Product Size | 生产能力 Capacity | 介质压力 Medium

pressure |

ZJ300 | 280-3100C | 1.3-1.5:1 | 0.3-10µm | 10-50kg/h | 1.6-2.5MPa |

ZJ800 | 280-3100C | 1.3-1.5:1 | 0.3-10µm | 200-400kg/h | 1.6-2.5MPa |

ZJ1000 | 280-3100C | 1.3-1.5:1 | 0.3-10µm | 1.5-2t/h | 1.6-2.5MPa |

ZJ1100 | 280-3100C | 1.3-1.5:1 | 0.3-10µm | 2-3t/h | 1.6-2.5MPa |

ZJ1200 | 280-3100C | 1.3-1.5:1 | 0.3-10µm | 3-4t/h | 1.6-2.5MPa |

Application of the scene: