Special crushing and grading equipment for glass powder

The material propertie:

Glass powder is a kind of inorganic square hard ultra-fine powder with white appearance. It is a kind of high scratch resistance transparent powder with small particle size, good dispersion, high transparency and good anti-sinking effect. Its whiteness 94, average particle size 2.5 0.5um, specific weight 2.7g/ml, oil absorption 28 2.5g/100g, Mohr hardness 7.8, chemical composition: silicates.

The material used:

Glass powder is mainly used as crystal primer in the production of high-grade furniture. It is also widely used as an undercoat paint for decoration. Scope of application: polyester paint, polyurethane paint, nitrocellulose paint, alkyd paint, acrylic paint, vinyl acid paint, PE transparent primer.

Equipment selection:

Zhongjin airflow crusher classifier, this group of equipment strictly control the distribution of particles, ensure the qualified collection rate and yield rate. Full set of production lines for our company mature process, stable equipment performance, constant operating parameters, reliable quality.

The application type:

Zj-qlm series, zj-f series

The working principle of:

ZJ series ultra-fine and ultra-micro air flow crusher USES several relatively arranged nozzles to form high-speed air flow, and then USES high-speed air flow to accelerate materials to supersonic speed and make them collide with each other at the intersection of nozzles, so as to achieve the purpose of ultra-fine grinding. Crushed material into the classifier classification chamber with the increased flow, due to the grading rotor high-speed rotation, is constrained by the particle grading rotor produced by centrifugal force, and by airflow, and the centrifugal force generated by viscous, when particles by centrifugal force is greater than the centripetal force, the grading size more than coarse particle crushing chamber to continue to shock crushing, fine particles with the air flow in cyclone separator, the trap to collect, the gas is removed by induced draft fan.

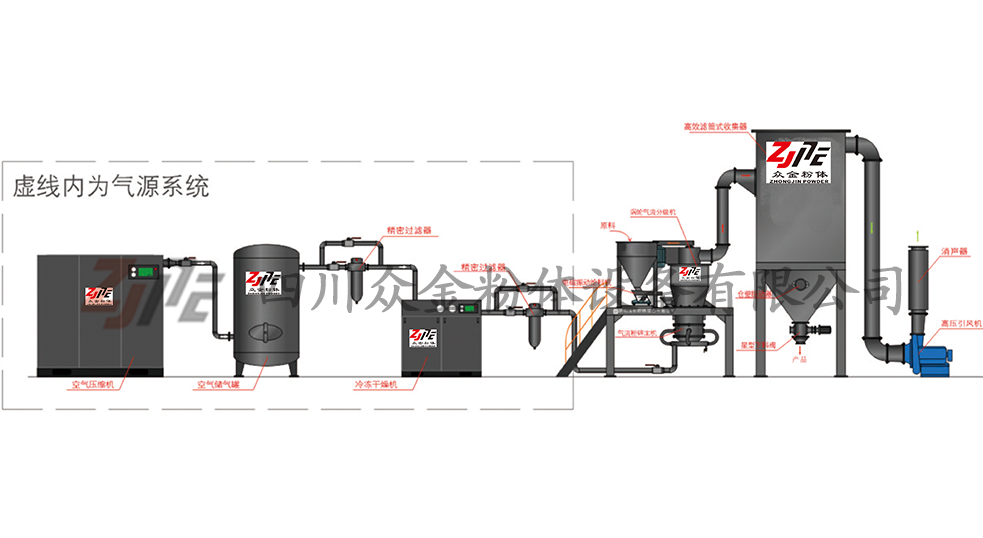

The process flow:

equipment:

ZJ series airflow crusher is the replacement of traditional fluidized bed airflow crusher, jet airflow crusher, horizontal airflow crusher and other types of airflow crusher. The best characteristic of this machine is to make full use of jet energy.

Characteristics of the equipment:

1Avoid mixing impurities into the material to ensure the quality of the material.

2No water, washing, completely dry production, a production can be completed to get a better particle size distribution, no pollution of micro powder materials, single number yield of more than 75%.

3Complete, stable and uniform flow field control technology; The design technology of constant gas-solid concentration ratio in crushing chamber ensures the system to run stably for a long time.

4. Reasonable flow field design and special wear-resistant treatment are adopted for the parts that are easy to be worn, which greatly reduces the wear of the equipment and extends the service life. The classification accuracy is high, the cutting particle size is more accurate, the required speed is lower, and the service life is long.

5 full fluidization state, can obtain excellent spherical particle shape; Qualified micropowders are immediately graded to avoid overgrinding. The company's unique variable frequency feeding system is conducive to the dispersion of materials, to ensure the continuous uniform and stable feeding, and to the control of product particle size.

6The complete and stable flow field established by high efficiency and high precision classifier can strictly limit the production of large particles and obtain excellent particle size distribution and high and narrow particle size range. In particular, the core competitive advantage of more thorough extraction and better stability of fine powder has been widely recognized in the industry.

7Once the operating parameters of the equipment are adjusted and fixed, the operation is stable, and there is no difference or change when the machine is started continuously for a long time.

8Fully closed negative pressure operation, low temperature grinding, high purity operation, no dust pollution, system emissions of 5mg/m3. The crushing chamber is equipped with an automatic slag discharge device, which can automatically remove the refractory particles and impurities in the materials. It has the function of breaking up and dispersing the aggregate materials. Large flow of air means cooling and grinding, which can be used for the processing of heat-sensitive materials, without deposition problem range:

Application of the scene: