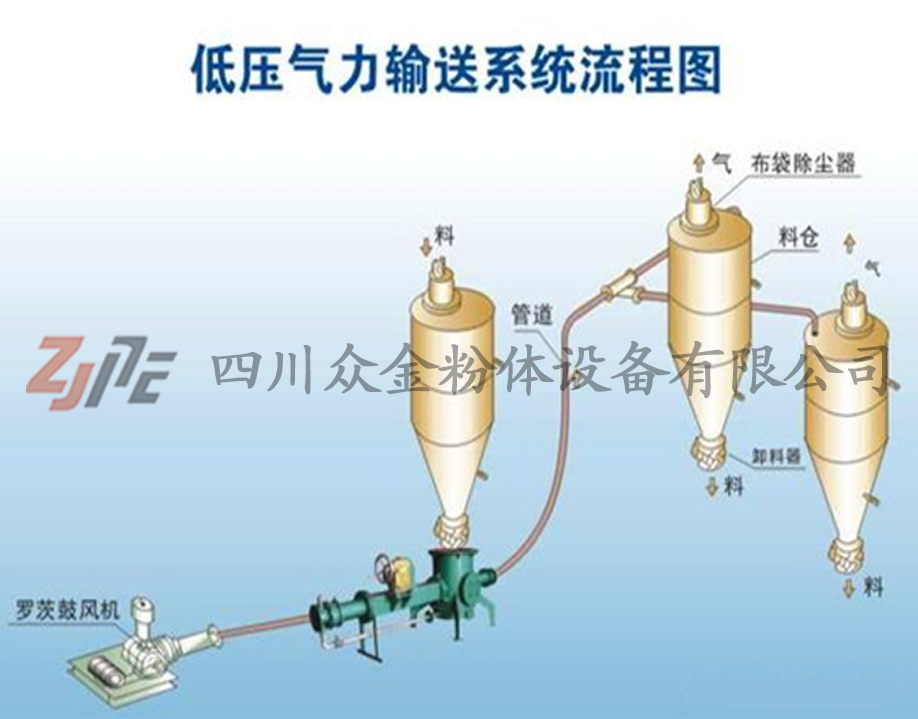

Low pressure pneumatic conveying system

The rapid development of science and technology in China has made the pneumatic conveying market prosperous. The appearance of zhongjin powder micro-positive pressure pneumatic conveying equipment meets the development of The Times. Under the general trend, the material sealing pump has the reliability that other conveying systems cannot achieve. Zhongjin powder has made great efforts in the design of powder conveying pump equipment, and has made great efforts to make the material sealing pump exert its power on the pneumatic conveying road in the future.

Pneumatic conveying pump is a new type of pneumatic conveying equipment, powder is specially used to transport cement, raw material, fly ash, a new type of low pressure conveying alumina powder equipment, using high speed air ejector function to transport dry loose materials, the equivalent distance is 450 m, height of 40 m within the scope of effect is ideal, in a complete set of ash conveying system, is expected to pump is the core equipment, thermal power plant, cement industry seal pump feeding material choice, can improve the efficiency of the overall transport, environmental protection enterprise production. Material seal pump structure is simple, less operation, can continue to send ash, automatically adjust the material seal pump output, to achieve a better effect of collecting and conveying cement, ash medium pressure is low, pipeline valve is not suitable for wear;

Advantages of zhongjin powder pneumatic conveying pump equipment: good dust control effect; Facilitate the realization of mechanization, automation, can reduce labor intensity, save manpower; In the conveying process, a variety of process operations can be carried out simultaneously, such as mixing, crushing, sorting, drying and cooling; It is used in foundry, metallurgy, chemical industry, building materials, grain processing and so on. The low-pressure pneumatic continuous conveying system composed of low-pressure continuous conveying pump has the reliability that cannot be achieved by the conveying system composed of any other pneumatic conveying equipment. Continuous conveying pressure is stable without any impact load. The equipment body is simple, and there is no frequent action of valve in conventional silo pump pneumatic conveying process, so the equipment fault is greatly reduced.

Low pressure pneumatic pump

Product overview

Zj-qlb series pneumatic conveying pump is an ideal equipment for conveying powdery materials with new low pressure pneumatic conveying developed

and designed by our factory. The product is widely used in power ash removal, building materials transfer, large construction sites and other industries in the medium and short distance of ash collection and transmission, not subject to terrain, ground features, height difference restrictions, closed, pollution-free, simple structure, small maintenance. According to the distance of different air sources can choose centrifugal fans, roots fans, compressed air and other air sources.

The working principle of

The material enters the chamber uniformly and constantlyfrom the air lock, and after fluidized once through the fluidized box, it has a tendency to flow to the nozzle. A negative pressure zone is formed between the nozzle and neventuri pipe, and the fluidized material is sucked into the mixing pipe, and then decelerated and pressurized by the diffusion pipe, so that the material is transported to the destination.

Conditions of use

The pump operation mode: continuous, intermittent. The air source pressure has wide adaptability, and the working pressure is 50-100kpa, depending on the conveying distance and the conveying quantity. Conveying distance < 250 m, height < 32 m, temperature - 20 ℃ ~ 150 ℃, conveying air velocity and size of the pipeline, also with different distance transport capacity and transport, and can according to what ZJ had - commonly QLB continuous pump series matching table to choose from.

name | model | Transmission capacity | Air inlet | Out of the mouth | Form a complete set of fan |

Low pressure pneumatic pump

| ZJ-QLB30-5 | 0~5t/h | DN100 | DN125 | 10-15m3/min |

ZJ-QLB30-10 | 5~10t/h | DN125 | DN150 | 15-25 m3/min |

ZJ-QLB40-15 | 10~15t/h | DN125 | DN170 | 25-35m3/min |

ZJ-QLB40-20 | 15~20t/h | DN150 | DN200 | 35-45 m3/min |

ZJ-QLB50-25 | 20~25t/h | DN200 | DN250 | 45-55 m3/min |

Application of the scene: