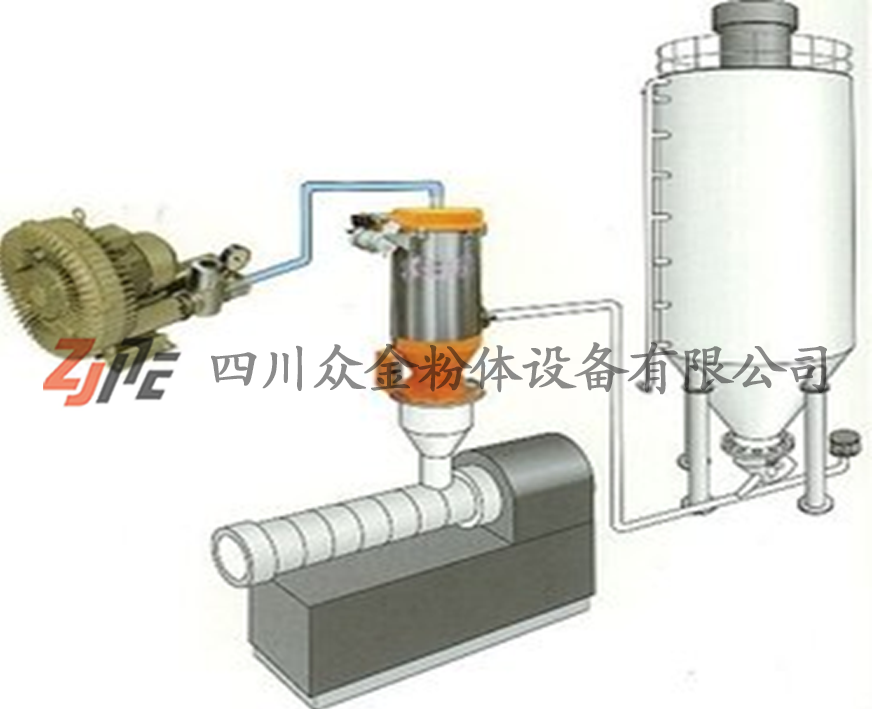

Vacuum feeding system of mixer

Product details:

Use a vacuum feeder

The vacuum conveyor realizes automatic feeding into the mixer to reduce dust pollution in the workshop and labor intensity.

Performance is introduced:

It can realize automatic feeding, flange connection to avoid dust leakage in the mixing process. Special nitrogen supplement device can be used in chemical plant with high explosion-proof requirement. The vacuum feeder has been widely used in food, chemical, pharmaceutical, new materials and other industries.

4/5000

The working principle of:

A) the vacuum pump generates vacuum through the separation vessel of the vacuum conveying equipment. The material is inhaled from the inlet through the suction hose and the suction port.

B) separate air and materials in the filtration bin of the separation vessel and collect the materials in the bin. Cyclone separator prevents fine powder from entering the filter to improve the efficiency of the filter.

C) when the bin is filled with materials, the vacuum pump will close automatically and the pressure in the conveying equipment will be balanced. The discharge valve opens, and the material flows out through the discharge port and directly falls into the storage container.

Product features:

The whole conveying process is completed in an airtight state to eliminate dust pollution and injury to the working environment, surrounding environment and operators. Full automatic control, eliminate the error caused by personnel operation. Strong applicability can be used with a variety of equipment to give feeding. No moving parts, low maintenance cost, quick card connection, easy cleaning.

Application of the scene: