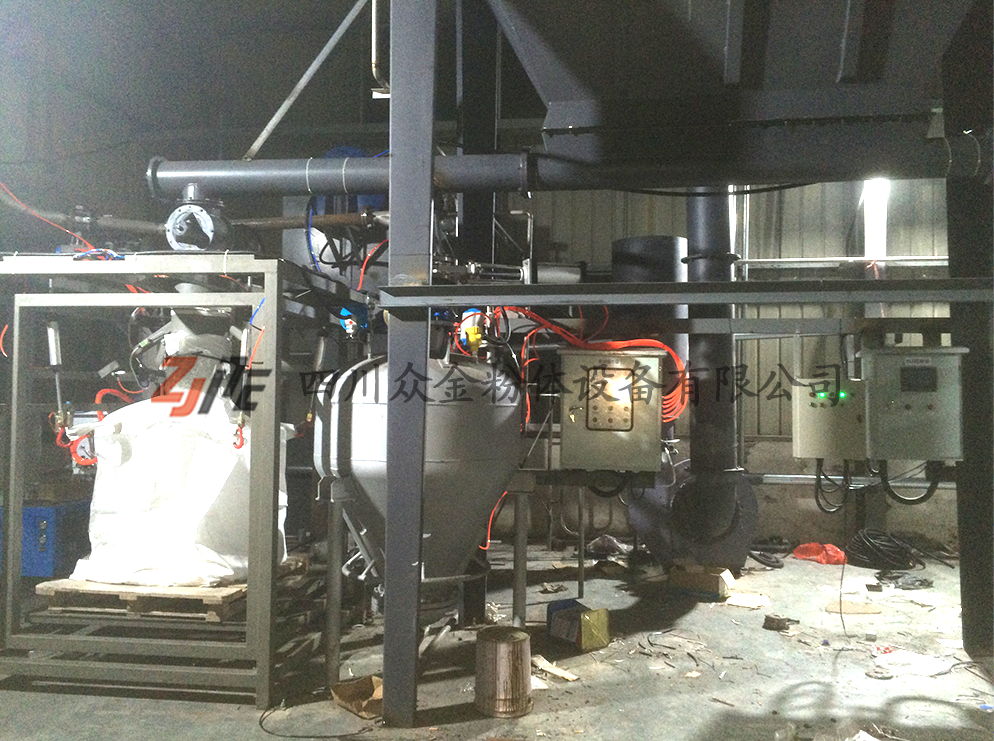

Positive pressure dense phase pneumatic conveying

Product details:

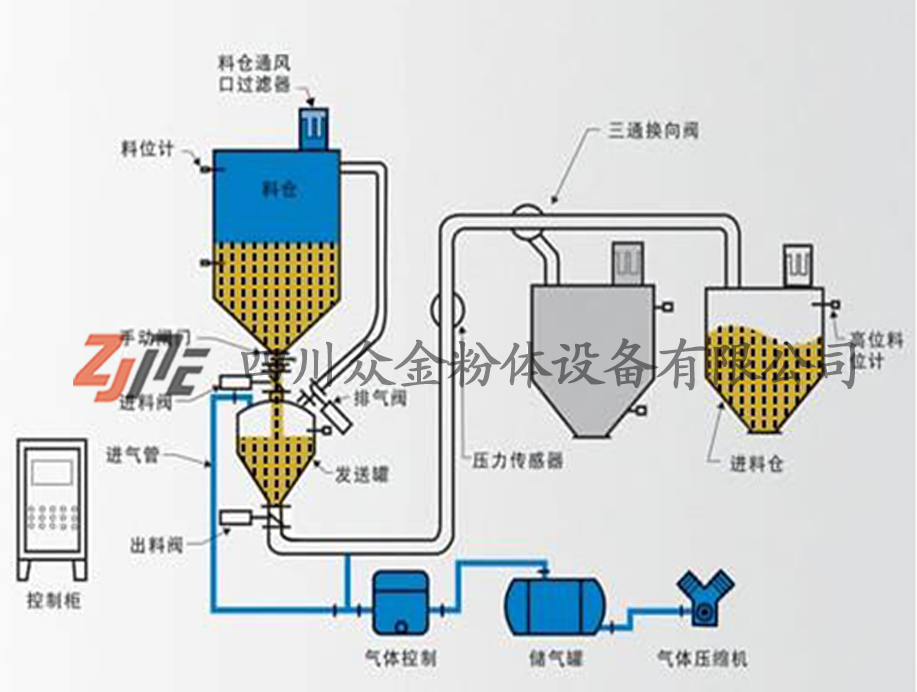

Positive pressure dense phase pneumatic transmission is the use of compressed gas as a power source, the use of mandatory pneumatic transmission, rely on closed pressure vessel (sending tank) as a transmitter, the general air pressure is 0.5

Mpa ~ 0.7mpa, the operating pressure is 0.3-0.5mpa, the sending tank can only adopt the intermittent conveying mode, and the conveying path can reach more than 1000m.

The working principle of:

Product features:

1. Low flow rate but large conveying capacity, almost no influence on material quality;

2. The system has high pressure and small gas consumption;

3. Automatic control system, high requirements for various electrical components;

4. Multi-point feeding and multi-point unloading;

5. Sending tank (also known as silo pump) is a pressure vessel, which is a mandatory signing equipment;

Due to the effect of pressure, material from sent tanks into the duct, compressed gas by the opening of the solenoid valve must be frequency pulse airflow (air knife), with the help of air blade pressure is greater than sending anchored material cutting ChengLiao tank pressure, depending on the material before and after the bolt static pressure difference as a driving force, the material forward, reached after separation device implementation of feed gas separation, material falling into a bunker, gas discharged into the atmosphere, implementation.

6. The air source is generally screw air compressor, and the post-processing equipment must be matched;

7. Reliable system requires less maintenance, but requires high quality of operating technicians.

Application of the scene: